Parts of a Farm Tractor: Maximizing Efficiency and Minimizing Costs

Farming demands peak performance from your equipment. Downtime translates directly to lost revenue, making smart purchasing decisions crucial. This guide explores how to save significantly on farm tractor parts—up to 30%—without compromising your operation's efficiency or safety. We'll navigate the choices between Original Equipment Manufacturer (OEM) and aftermarket parts, guiding you toward informed decisions that benefit your bottom line and your farm's sustainability. For sprayer tank options, check out these helpful resources.

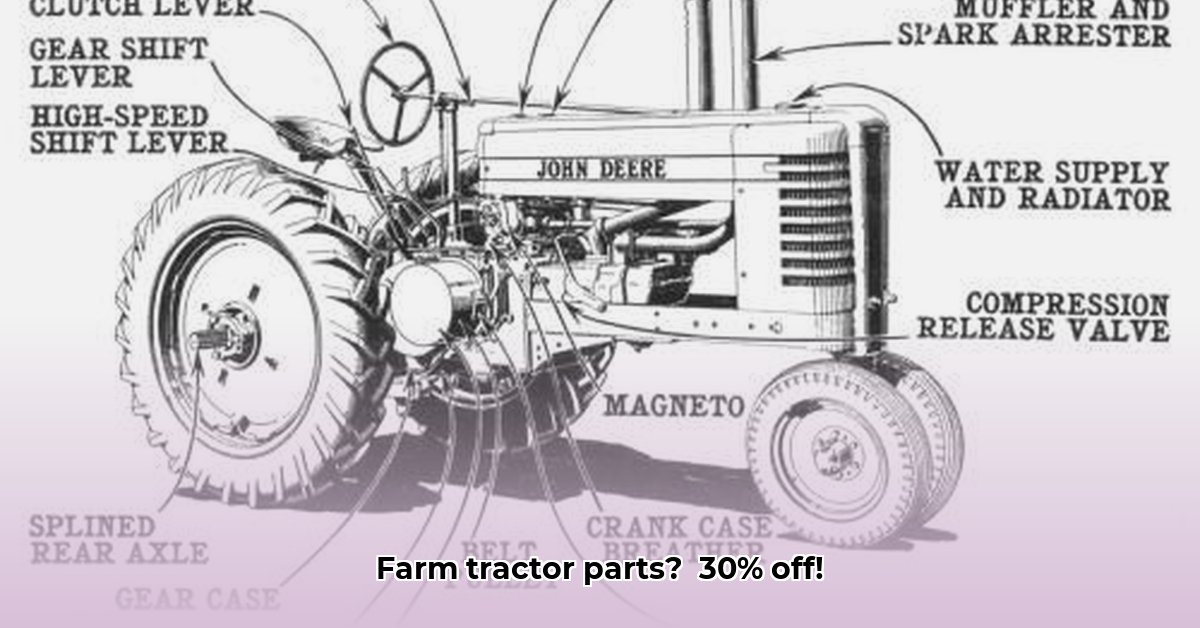

Understanding Your Tractor's Vital Systems

Before examining cost-saving strategies, let's review your tractor's key components:

- Engine: The powerhouse, demanding regular maintenance of filters, belts, and spark plugs. Smart choices here directly impact fuel efficiency and operational lifespan. Don't underestimate the long-term savings of high-quality engine parts.

- Transmission: This crucial system transmits power from the engine to the wheels. Transmission failures are notoriously expensive, highlighting the importance of choosing reliable parts.

- Hydraulic System: Essential for various operations, like lifting implements and running attachments. Hydraulic pumps and cylinders represent significant investments; prioritizing quality is paramount.

- Drivetrain: Axles, differentials, and universal joints endure substantial stress, emphasizing the need for durable and appropriately selected components.

- Electrical System: Powers essential functions, from lighting to sophisticated electronics. Malfunctions disrupt operations, making preventative maintenance and smart part choices essential.

- Steering System: Ensures safe and precise control. Failure can mean costly delays and safety risks. Prioritize reliability in this critical system.

- Braking System: Safety is paramount. While aftermarket options exist, the superior performance and reliability of OEM brake parts often justify their higher cost.

- Implement Attachments: The tools that perform specific tasks. Cost varies greatly depending on the implement and part required. Choosing wisely can significantly improve operational efficiency.

OEM vs. Aftermarket: A Detailed Cost Analysis

The choice between Original Equipment Manufacturer (OEM) and aftermarket parts is pivotal in managing farm expenses. OEM parts offer a guaranteed fit and come with comprehensive warranties. However, they typically cost more. Aftermarket options offer potential savings (up to 30%), but their quality and longevity vary.

| Feature | OEM Parts | Aftermarket Parts |

|---|---|---|

| Cost | Higher | Lower |

| Warranty | Typically comprehensive | Variable; carefully examine warranty details |

| Reliability | Generally superior | Variable, depending on the manufacturer |

| Availability | Usually readily available | Availability may less consistent |

| Fit & Function | Guaranteed fit | May require verification; potential adjustments |

Strategic Part Selection: Maximizing Value for Your Farm

Making informed decisions requires a balanced approach. Here's a step-by-step strategy:

- Thorough Research: Investigate various parts and suppliers. Compare specifications, read independent reviews, and assess supplier reliability. This step is crucial for long-term cost savings.

- Prioritize Critical Components: For essential parts like engine components or brakes, the added expense of OEM parts often outweighs the risk of failure.

- Budgeting and Needs Assessment: Balance costs with your farm's specific needs. Aftermarket parts can be suitable for less critical components.

- Risk Assessment: Weigh the potential risks of failure against the cost savings of aftermarket parts. This assessment is unique to each farm's operations and risk tolerance.

- Supplier Diversification: Avoid relying on a single supplier to mitigate supply chain disruptions.

- Preventative Maintenance: Regular maintenance extends part lifespan, maximizing your investment regardless of origin. This is a crucial element in cost-effective farming.

- Sustainability Considerations: Research suppliers committed to environmentally friendly manufacturing practices. This aligns with sustainable agriculture while often improving the overall quality of parts.

Isn't it true that a proactive approach to parts management can significantly reduce unexpected downtime and repair costs? This is a critical aspect often overlooked in budget planning.

Case Study: John's Success with Smart Purchasing

John, a dairy farmer, successfully reduced repair bills by 25% by strategically using aftermarket parts for less critical wear items. His success stems from meticulous research, preventative maintenance, and a carefully planned purchasing approach. He highlights the importance of understanding your equipment and prioritizing quality where it matters most.

Sustainability: Eco-Friendly Parts and Practices

The environmental impact of farming is increasingly important. Choosing suppliers committed to sustainable manufacturing practices aligns with this responsibility and often leads to better product quality. Consider parts made from recycled materials and manufacturers invested in reducing their carbon footprint. This approach can create a positive image and foster customer loyalty while promoting long-term sustainability.

Key Takeaways:

- Aftermarket parts offer the potential for substantial cost savings.

- Careful part selection is paramount to avoid failures and associated downtime.

- Balancing cost, quality, and need is essential for maximizing return on investment. Reputable suppliers often offer warranties that protect against inferior parts.

- Incorporating sustainable sourcing practices into your purchasing decisions is environmentally responsible and often improves long-term efficiency.

- Preventative maintenance is key to extending part life and minimizing overall costs.